CHICAGO — Automation has been on the rise in laundry and linen services for some time, but with the effects of the past few years, some operations are taking a closer look at their operations.

In the most recent American Laundry News Your Views survey, readers were asked about current and future automation activities in their plants.

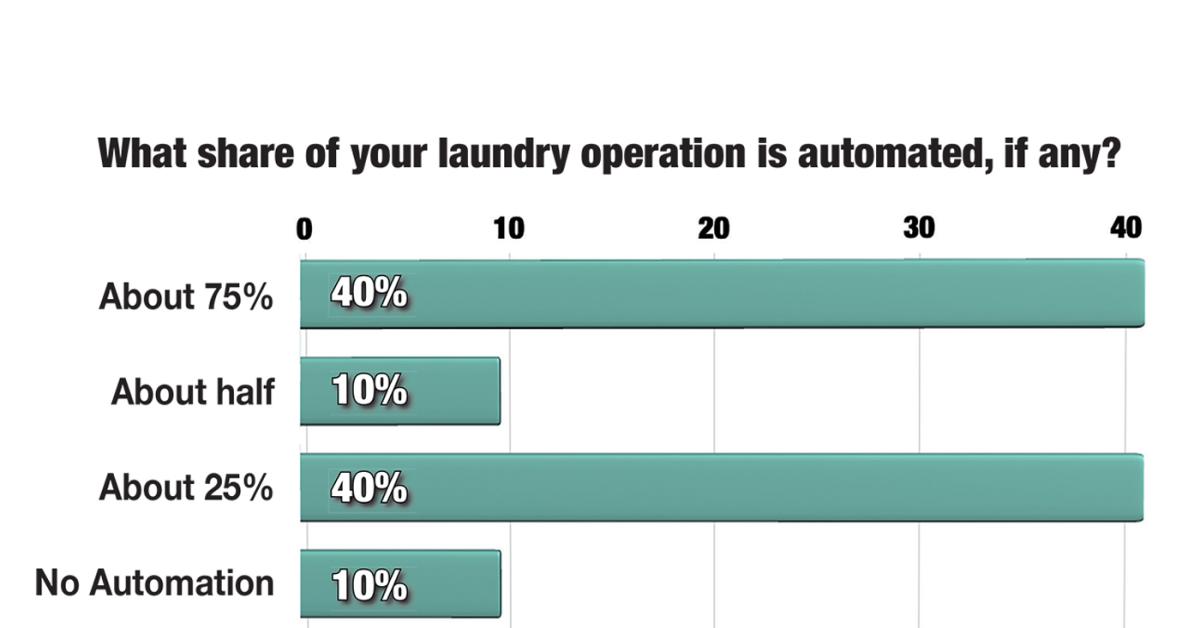

When asked how much of their operations are automated, 40% of respondents indicate 75% of their plants are automated. Those whose operations are 25% automated were also 40%.

Survey takers who say half or none of their plants are automated were both 10%.

The area of facilities most automated is finishing, according to 30% of respondents. That’s followed by folding (26.7%) and wash (16.7%).

Soil sort and drying were each indicated by 13.3% of those who took the survey.

90% of respondents say their laundry has seriously considered automation in the past five years. And a major reason for that consideration is labor challenges.

“The more labor costs go up, it just makes sense,” a respondent writes. “We are in New York, so in addition to labor costs increasing 10-15% every year, there are many added regulations that go along with it, increasing the incentive to reduce manual labor.

“The problem being is in New York state, the population and customer base is shrinking, which ultimately shrinks the volume.”

Other reasons for considering automation include “expansion,” “to improve efficiency in the plant, and “reduce labor costs and injuries.”

One respondent whose laundry isn’t looking at automation says that’s because the “cost to install a system for RFIDs on our garments is not in our budget.”

When asked “what areas of your operation would you like to automate in the future,” respondents indicated:

- Soil sort, 25%

- Dry, 16.7%

- Wash, 12.5%

- Finish, 20.8%

- Fold, 20.8%

- Other (total automatic cart washing and transport system), 4.2%

With the awareness and use of artificial intelligence on the rise, opinions on the progression of AI in laundry automation are mixed.

- It’s off to a good start but has a way to go.

- I would have to review it.

- Good.

- None at this time.

- I’m excited to see what our options will be.

- It’s amazing to see this technology but it is scary to think how easy it can be to replace humans in the workforce.

The most important reason for respondents’ laundries to automate is, of course, labor (60%) followed by cost savings and efficiency, both at 20%.

Not surprisingly, price is the greatest deterrent to using or increasing automation, according to 42.9% of respondents. That’s followed by “upper management moving slowly” at 21.4%.

Selecting the right equipment has slowed 14.3% of survey takers, and 7.1% are still analyzing their operations and choosing the right vendor partner.

And 7.1% of respondents say their plants don’t need any further automation at this time.

Finally, one respondent cautions, “Just because it is automated doesn’t mean it’s better.”

While the Your Views survey presents a snapshot of readers’ viewpoints at a particular moment, it should not be considered scientific. Due to rounding, percentages may not add up to 100%.

Subscribers to American Laundry News e-mails are invited to take the industry survey anonymously online each quarter. All managers and administrators of institutional/OPL, cooperative, commercial and industrial laundries are encouraged to participate, as a greater number of responses will help to better define operator opinions and identify industry trends.

Have a question or comment? E-mail our editor Matt Poe at [email protected].