Each year, a number of laundry projects are completed around the country, resulting in brand-new or retrofitted plants primed and ready to convert soiled goods to clean textiles for the benefit of end-users and customers.

But before one of these plants goes online, there are months, sometimes even years, of effort spent in preparation. As a way to celebrate all the hard work that goes into funding, designing, building and equipping a modern laundry plant, American Laundry News has created this feature coined Designing Success to feature portraits of memorable plant installations.

Here, institutional/OPL, commercial and industrial laundry equipment manufacturers, as well as firms that offer design/build, engineering and mechanical contracting services to the laundry industry, were invited to tout their latest and greatest projects of the past two years.

EDRO CORP., FOR HALAWA CORRECTIONAL

Halawa Correctional, Aiea, Honolulu, Hawaii, is the largest prison facility in that state’s prison system. Operated by the Hawaii Department of Public Safety, Halawa Correctional houses approximately 1,500 inmates in two separate facilities: a special-needs facility and a medium-security facility. The main laundry serves the prison system’s population with the throughput capacity to produce 2 million pounds of laundry per year.

The facility was searching for technology that would limit water consumption yet maximize wash-room capacity within the boundaries of the existing space limitations at Halawa Correctional. EDRO Corp. was able to partner with a utility consultant and combine its ozone-powered washer-extractors with a water treatment system to reuse wash water and limit sewer discharge.

To maximize wash capacity per square foot, EDRO utilized its “ER” washer-extractor option, the company says. The “ER” variant reverses the positioning of electrical components and mirrors door-swing operation. This allows the placement of equipment adjacent to structures that would impede normal machine operation. By utilizing this option, the facility increased its washer throughput capacity by 50% in the same space.

Taking six months of work from start to finish, the installation was a main laundry upgrade project. Project included site design, removal of existing machinery, upgrade drain pit and foundation, and installation of new machines with upgrading of utility resources.

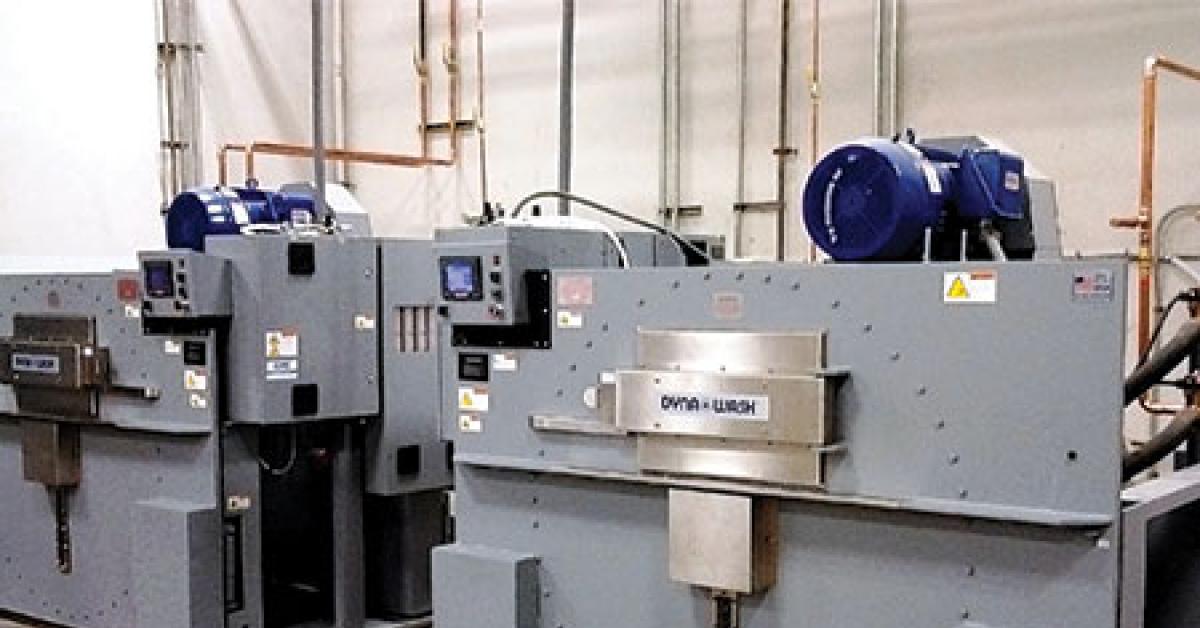

EDRO manufactured and supplied one DW300SM-DOS (a 300-pound end-loading washer-extractor), one DW300SMER-DOS (a 300-pound end-loading washer-extractor with “ER” option), and one CSL110 (a 110-pound open-pocket soft-mount washer-extractor).

The new DynaWash washer-extractors were fitted with inverters and single motor drives, an upgrade to the older multi-motor-drive set-up of the facility’s existing machines. Inverter with single-motor-drive technology is a tremendous advance in machine speed control and greatly reduced peak electrical load demand, EDRO says. This motor design has significantly fewer parts than a conventional multiple motor setup with single-speed motors, clutches and gearboxes, while delivering more speed selections and greater energy efficiency, the company adds.

Coupled with the programmability of the HMi/PLC, EDRO’s washer-extractors can deliver exacting cylinder RPMs for top wash results from wash speeds through high extract. Multiple parameter settings allow high-torque wash speeds with steep slope starts and stops, and elongated slopes for even load distribution and acceleration to high extract, EDRO says.

The High Slip Braking feature allows for braking torque in excess of 100% of full-load motor torque by controlling the deceleration from high speed to make the motor operate as a highly efficient induction generator. No additional parts are required to stop the machine.

Through the energy consultant, Halawa Correctional applied for utility rebates to assist in the funding for the new washers. EDRO also designed the wash aisle layout, oversaw machine installation, and provided start-up and training of the washers.

Client benefits include increased wash capacity from the same machinery footprint, lower wastewater discharge into the State of Hawaii public sewer system, and better utility utilization of water savings and electrical consumption.

Partnering with US Joiner and Noresco for installation and consultation, the Halawa Correctional Facility main laundry upgrade project cost $350,000, according to EDRO.

Check back throughout the month for more Designing Success stories!

Have a question or comment? E-mail our editor Matt Poe at [email protected].