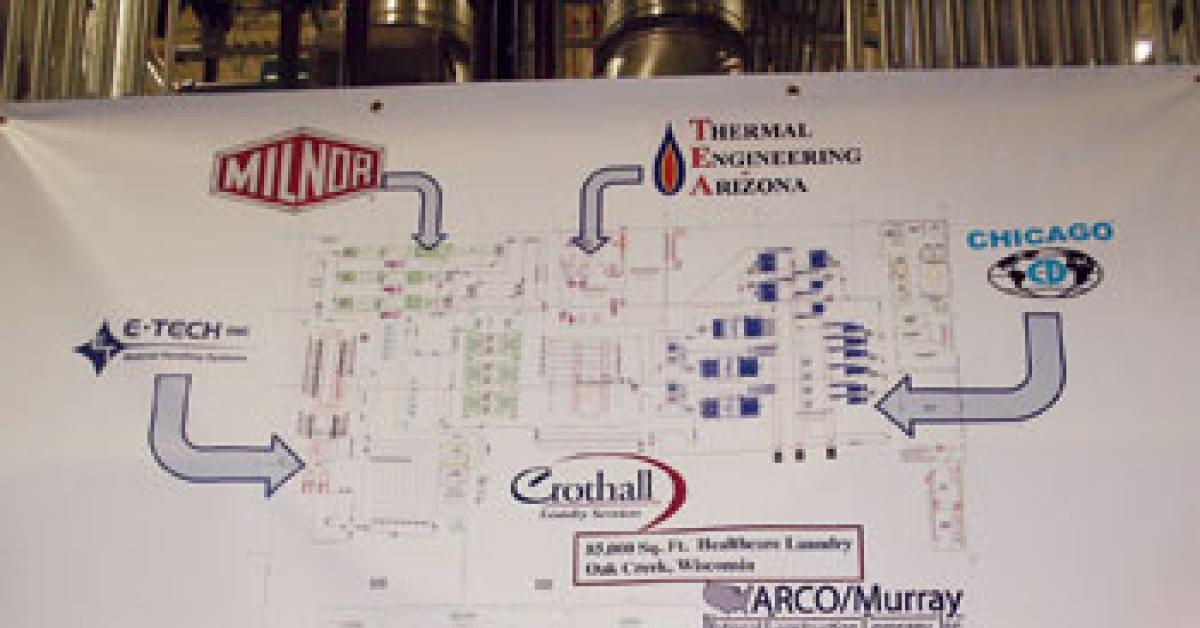

OAK CREEK, Wis. — When Crothall Laundry Services officially opened its new 83,000-square-foot plant during a June 27 ribbon-cutting ceremony, it marked a couple of important firsts for the Crothall Healthcare service line.

The $13 million state-of-the-art facility is the first that Crothall has built from the ground up, and it is reportedly the first laundry in the world to certify (its processing included) under certain LEED (Leadership in Energy and Environ-mental Design) standards. And Crothall managed to complete the construction project—aided by many industry vendors—in nine months.

The Oak Creek plant is one of the few facilities in the country to process laundry without using high-pressure steam boilers, Crothall says. Instead, a Thermal Engineering of Arizona (TEA) Steamless Water Treatment System—using natural gas-fired hot-water boilers and heat exchangers that recover heat from wastewater—provides all the hot water needed for washing.

A gas-fired steam tunnel from Colmac Industries used to condition lab coats generates its own steam independent of a traditional boiler.

Chicago Dryer Co. provided 42 pieces of flatwork finishing equipment to maximize the facility’s production output with minimal utility consumption and enhanced ergonomics.

There are two full ironing lines, each featuring an Edge Maxx cornerless spreader-feeder; Powerhouse self-contained, thermal-fluid, deep-chest ironer; Skyline large-piece folders and Bridge linen transition conveyors.

A small-piece ironing line includes a Rapid Feed small-piece vacuum feeding aid, Powerhouse ironer, Skyline folder and DrawBridge linen transition conveyors to move stacked product from the folder directly to the main conveyor.

There are dedicated systems for a variety of tumble-dried items, including three Blanket Blaster cornerless finishing systems, two Skyline fitted sheet and blanket folders and six Air Chicago folders. All have Bridge conveyors.

All feeding and folding equipment incorporates CHI•Touch, an advanced PC-based control system that offers optimum visualization of operating, electronic and mechanical machine functions, as well as real-time display of production numbers.

Crothall management can set, monitor and maintain desired standards and production levels. CHI•Touch guides employees through each step of machine operation and uses the same logic and uniform style display on every machine so staff members can easily switch to a different piece of equipment.

Have a question or comment? E-mail our editor Matt Poe at [email protected].